Aliva has been operating in the ventilated facade sector for more than 30 years and is a leader in the design and construction of systems. Ventilated facades play a fundamental role in relating to the urban context and ensure constant air circulation without hindering any architectural constraints.

Today, going more specifically - Aliva ventilated facades - we focus on their concrete and certified ability to prevent and not spread potential fires (internal or external to the building). Reaction to fire is one of the most relevant protection characteristics to guarantee an adequate level of safety in any building, both civil and industrial.

For years we have been working to ensure that all the products and all the solutions proposed by Aliva are concretely fireproof, how?

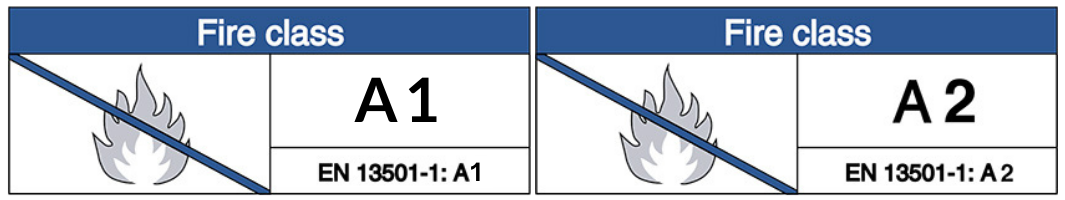

1. Using only and exclusively non-combustible materials, in fact all the products offered by Aliva in its ventilated facades are classified with the highest degree of reaction to fire existing today: A1 and A2 - according to the UNI EN 13501-1 standard. The reference standard defines non-combustible materials as: non-combustible products that prevent the facade from catching fire if there is a trigger (inside, outside or in any situation), making them the main material to choose for safe ventilated facades, as Aliva does.

2. By inserting ad hoc design tools, such as the compartmentalization of the envelope with fireproof sheets (between one floor and another) and "fire stop" elements, which expanding - if exposed to intense heat - obstruct the ventilation cavity, preventing a fire is generated and spreads inside the building or on neighboring structures. These and other devices are included in the facade project after a careful analysis of the case and if the situation requires it.

From these considerations it emerges how important and necessary it is to always choose certified products, components, solutions and systems, as well as quality.